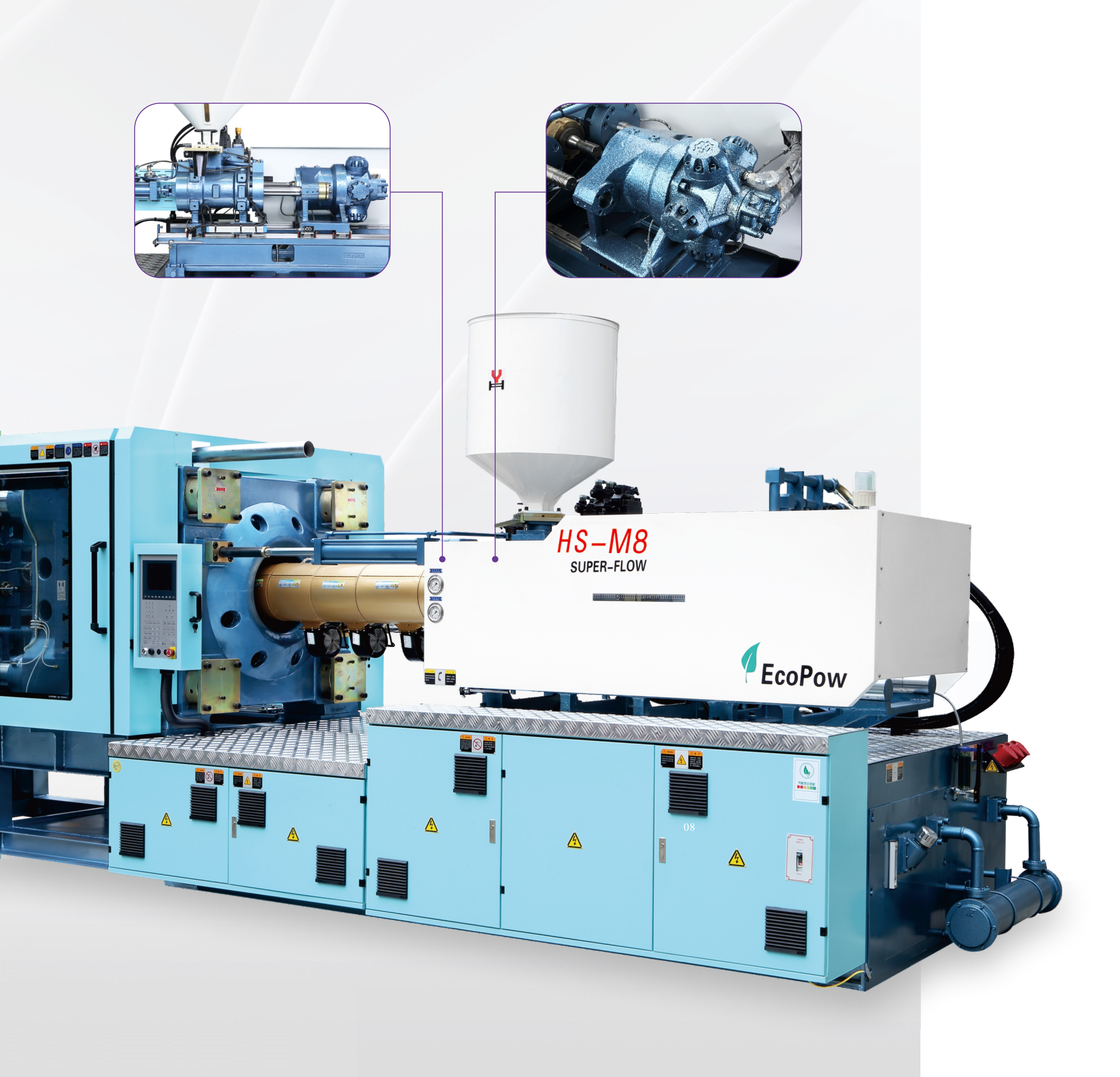

The servo injection molding machine is designed for a general purpose series of processing applications for end users. Haith Servo motor energy saving injection molding machine can help you reach a maximum producibility on a wide range of materials. with a Nitrided +Alloy screw & barrel. wear-resistant screw tip. High strength tie-bars and rigid platens. It all adds up to a unit, that will stay the course. The universal range of injection molding machines offers consistent high quality and high yields in a wide range of materials and in the most complex molds

Contact us, for SERVO energy saving injection molding machines at best price today!

Haishi creates independently the box type high rigidity mold structure for the clamping part; the clampinosupportguide rail adopts the high rigidity design to reduce the deformation effectively: the toggle structureoptimized anddesigned with computer achieves exceptionally stable and rapid clamping: and the enlaraed molcthickness, the gearmold regulation unit and the internally installed mechanical safety lock as well as the 180.dearee rotary productblanking bucket, all help achieve vour ind ividual demands and make vour operation easier .

The sled part of Haishi injection molder gives full expression to dedication to innovation and pursuit of perfection.

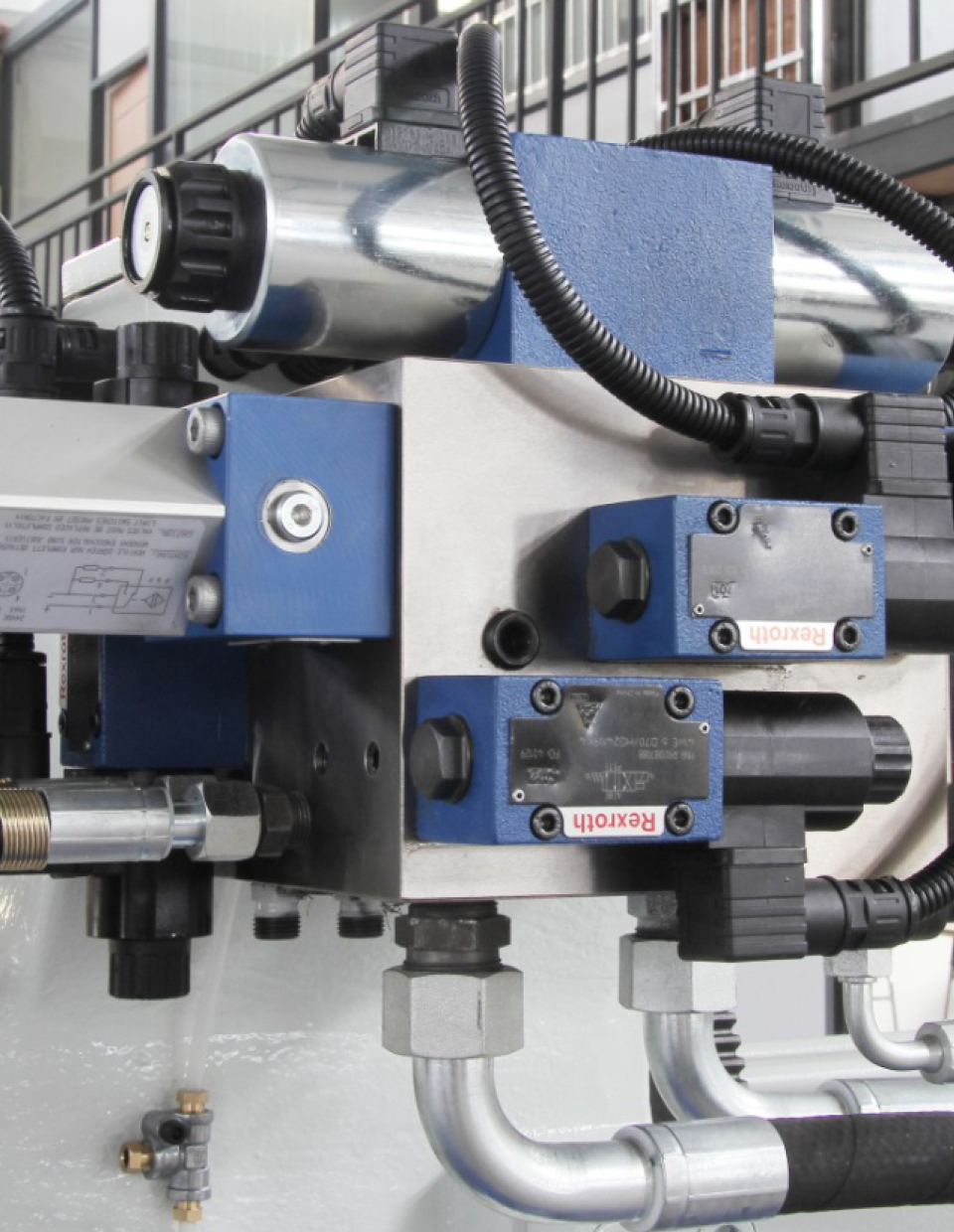

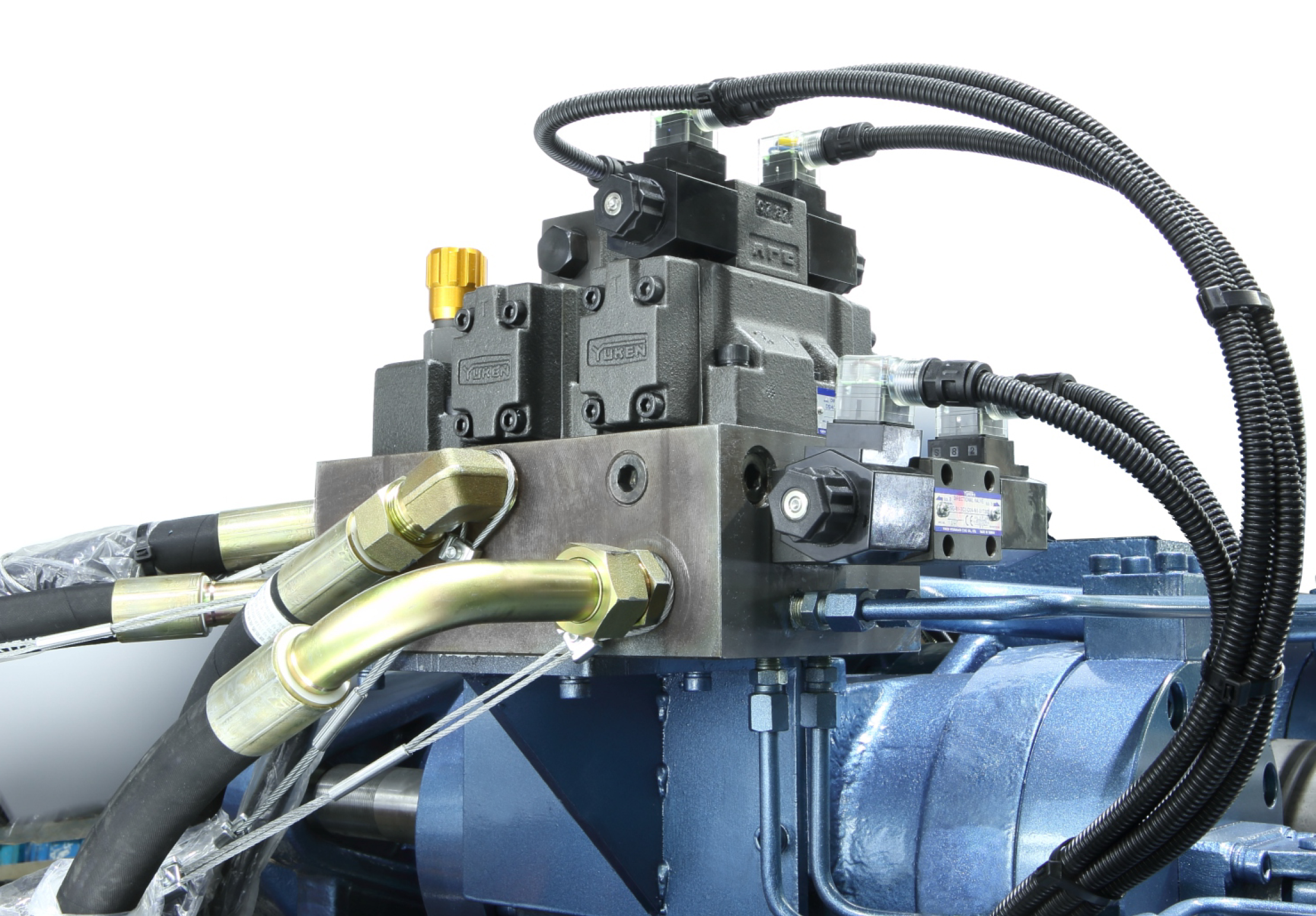

The oil way design of big bore under no resistance can lower the oil way loss and noise; it uses the advancecconfiguration, the servo control system, so it features energy saving capacity up to 20-80% and can achieve zero backpressure glue-smelting with plasticizing capacity and plasticizing effect improved by 60% compared with the traditionamachine; and it uses a high density filtering unit in order to control the greasy dirt at NASB8-9.

The whole control system of the injection molder features powerful function and stable performancewith high speed response. The controller is a new type of controller which is co-developed with arenowned injection molder computer supplier under the hosting of the professional and technicalpersonnel of our company. It uses highspeed stable DSPtechnique, combiningwith 16 bit high speed analog quantityinput, in order to achieve more precisedata detection box control; its displayuses high resolution LCD displayfeaturing advantages far above thecommon computers.

High-end configuration, super power saving effect and superior quality! The servo energy-saving injection molder has its outout power changing along with the load change, so there is nowaste of excessive energy. The motor at the cooling end doesn’t work with power consumption ot0. The servo energy-saving injection molder can save 20-80% compared with traditional injectionmolders. So it can bring you true experiences of power saving and great economic benefits.

| 说明 | DESCRIPTION UNIT | HS100 | HS138 | HS158 | HS180 | HS198 | HS238 | HS278 | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 国际公认型号 | INTERNATIONAL SIZE RATING | HS90 | HS110 | HS120 | HS160 | HS180 | HS200 | HS250 | |||||||||||||||

| 注射装置 | Injection Unit | 单位 | A | B | C | A | B | C | A | B | C | A | B | C | A | B | C | A | B | C | A | B | C |

| 螺杆直径 | Screw Diameter | mm | 30 | 35 | 40 | 38 | 42 | 45 | 38 | 42 | 45 | 42 | 45 | 50 | 45 | 50 | 55 | 45 | 50 | 55 | 55 | 60 | 65 |

| 螺杆长径比 | Screw L/D ration | L/D | 23.5 | 22 | 19.2 | 24 | 21.6 | 20.2 | 24.1 | 21.7 | 20.2 | 23.6 | 22 | 19.6 | 24.5 | 22 | 20 | 24.5 | 22 | 20 | 24.1 | 22 | 20.3 |

| 理论注射体积 | Shot volume | cm³ | 120 | 163 | 214 | 206 | 252 | 289 | 232 | 284 | 326 | 325 | 374 | 461 | 382 | 471 | 570 | 382 | 471 | 570 | 641 | 763 | 596 |

| 理论注射重量 | Shot weight (PS) | g | 109 | 149 | 194 | 185 | 227 | 260 | 211 | 258 | 296 | 296 | 340 | 420 | 347 | 429 | 519 | 347 | 429 | 519 | 584 | 695 | 815 |

| 注射压力 | Injection Pressure | Mpa | 283 | 208 | 160 | 200 | 163 | 143 | 226 | 185 | 161 | 218 | 190 | 154 | 221 | 179 | 148 | 221 | 179 | 148 | 202 | 170 | 145 |

| 最高螺杆转速 | Max screw speed | rpm | 240 | 240 | 240 | 240 | 240 | 240 | 220 | ||||||||||||||

| 锁模系统 | Clamping Unit | ||||||||||||||||||||||

| 锁模力 | Clamping Force | kN/T | 1000/100 | 1200/120 | 1500/150 | 1800/180 | 1900/190 | 2180/218 | 2680/268 | ||||||||||||||

| 开模行程 | Opening stroke | mm | 345 | 360 | 390 | 435 | 460 | 490 | 560 | ||||||||||||||

| 拉杆内间距 | Tie-bars distance | mm | 370x370 | 430x380 | 430x430 | 480x480 | 515x475 | 530x530 | 575x575 | ||||||||||||||

| 最大模厚 | Max.mold height | mm | 380 | 430 | 460 | 550 | 550 | 550 | 580 | ||||||||||||||

| 最小模厚 | Min.mold height | mm | 170 | 170 | 180 | 210 | 210 | 220 | 220 | ||||||||||||||

| 顶出行程 | Ejection stroke | mm | 91 | 120 | 118 | 135 | 135 | 146 | 135 | ||||||||||||||

| 顶出力 | Ejection force | kN | 38 | 45 | 53 | 62 | 62 | 80 | 91 | ||||||||||||||

| 其它 | OTHERS | ||||||||||||||||||||||

| 电马达功率 | Motor power | kW | 15 | 15 | 19 | 25 | 25 | 31 | 31 | ||||||||||||||

| 加热功率 | Heating capacity | kW | 7.2 | 7.3 | 7.4 | 9.9 | 11.5 | 11.5 | 13.5 | ||||||||||||||

| 油箱容量 | Oiltank Capacity | Litre | 157 | 215 | 220 | 300 | 305 | 310 | 330 | ||||||||||||||

| 机器尺寸 | Machine Dimensions | m | 4.4x1.15x1.8 | 4.71x1.28x2.1 | 4.82x1.28x2.1 | 5.31x1.4x2.2 | 5.4x1.45x2.25 | 5.6x1.44x2.3 | 6.2x1.63x2.32 | ||||||||||||||

| 机器重量 | Machine Weight | Kg/T | 3.5 | 4.2 | 4.5 | 5.65 | 6.1 | 7.1 | 8.5 | ||||||||||||||

| 模板尺寸 |  |

|

|

|

|

|

|

||||||||||||||||

| 说明 | DESCRIPTION UNIT | HS298 | HS330 | HS400 | HS450 | HS530 | HS630 | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 国际公认型号 | INTERNATIONAL SIZE RATING | HS280 | HS320 | HS380 | HS450 | HS530 | HS600 | |||||||||||||

| 注射装置 | Injection Unit | 单位 | A | B | C | A | B | C | A | B | C | A | B | C | A | B | C | A | B | C |

| 螺杆直径 | Screw Diameter | mm | 60 | 65 | 70 | 65 | 70 | 75 | 70 | 75 | 80 | 70 | 75 | 80 | 75 | 80 | 85 | 90 | 95 | 100 |

| 螺杆长径比 | Screw L/D ration | L/D | 23.8 | 22 | 20.2 | 23.8 | 22 | 20.6 | 23.6 | 22 | 20.5 | 23.6 | 22 | 20.5 | 23.1 | 21.7 | 20.4 | 23.2 | 22 | 20.9 |

| 理论注射体积 | Shot volume | cm³ | 777 | 912 | 1058 | 1161 | 1347 | 1546 | 1501 | 1723 | 1960 | 1501 | 1723 | 1960 | 1727 | 1965 | 2219 | 2544 | 2834 | 3140 |

| 理论注射重量 | Shot weight (PS) | g | 707 | 830 | 963 | 1057 | 1226 | 1407 | 1366 | 1568 | 1784 | 1366 | 1568 | 1784 | 1572 | 1788 | 2019 | 2315 | 2579 | 2857 |

| 注射压力 | Injection Pressure | Mpa | 210 | 176 | 150 | 208 | 179 | 156 | 199 | 173 | 152 | 199 | 173 | 152 | 186 | 164 | 145 | 184 | 165 | 149 |

| 最高螺杆转速 | Max screw speed | rpm | 200 | 192 | 170 | 170 | 150 | 150 | ||||||||||||

| 锁模系统 | Clamping Unit | |||||||||||||||||||

| 锁模力 | Clamping Force | kN/T | 2800/280 | 3300/330 | 4000/400 | 4500/450 | 5300/530 | 6300/630 | ||||||||||||

| 开模行程 | Opening stroke | mm | 590 | 720 | 720 | 800 | 860 | 910 | ||||||||||||

| 拉杆内间距 | Tie-bars distance | mm | 620x620 | 725x675 | 730x730 | 825x775 | 865x805 | 920x865 | ||||||||||||

| 最大模厚 | Max.mold height | mm | 630 | 680 | 800 | 800 | 830 | 900 | ||||||||||||

| 最小模厚 | Min.mold height | mm | 220 | 300 | 330 | 330 | 350 | 350 | ||||||||||||

| 顶出行程 | Ejection stroke | mm | 150 | 160 | 180 | 200 | 241 | 295 | ||||||||||||

| 顶出力 | Ejection force | kN | 91 | 102 | 113 | 113 | 152 | 152 | ||||||||||||

| 其它 | OTHERS | |||||||||||||||||||

| 电马达功率 | Motor power | kW | 31 | 50 | 62 | 62 | 50+31 | 50+31 | ||||||||||||

| 加热功率 | Heating capacity | kW | 18.3 | 22.8 | 29.5 | 29.5 | 33.5 | 42.8 | ||||||||||||

| 油箱容量 | Oiltank Capacity | Litre | 450 | 690 | 770 | 950 | 950 | 950 | ||||||||||||

| 机器尺寸 | Machine Dimensions | m | 6.37x1.73x2.36 | 7.7x2.0x2.36 | 7.8x2.1x2.37 | 8.53x2.2x2.4 | 9.1x2.2x2.8 | 10.2x2.2x2.71 | ||||||||||||

| 机器重量 | Machine weight | Kg/T | 11 | 13.3 | 14.7 | 17.4 | 26 | 30 | ||||||||||||

| 模板尺寸 |  |

|

|

|

|

|

||||||||||||||

| 说明 | DESCRIPTION UNIT | HS750 | HS900 | HS1200 | HS1400 | HS1700 | HS2200 | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 国际公认型号 | INTERNATIONAL SIZE RATING | HS700 | HS900 | HS1200 | HS1400 | HS1700 | HS2200 | |||||||||||||||||||

| 注射装置 | Injection Unit | 单位 | A | B | C | D | A | B | C | D | A | B | C | D | A | B | C | D | A | B | C | D | A | B | C | D |

| 螺杆直径 | Screw Diameter | mm | 90 | 95 | 105 | 110 | 95 | 100 | 105 | 110 | 105 | 115 | 125 | 135 | 110 | 120 | 130 | 140 | 120 | 130 | 140 | 150 | 130 | 140 | 150 | 160 |

| 螺杆长径比 | Screw L/D ration | L/D | 25.3 | 24 | 21.7 | 20.7 | 24.2 | 23 | 21.9 | 20.9 | 22 | 20 | 19 | 17 | 25 | 23 | 21 | 20 | 25 | 23 | 21 | 20 | 25 | 23 | 21 | 20 |

| 理论注射体积 | Shot volume | cm³ | 2925 | 3259 | 3982 | 4369 | 3544 | 3927 | 4330 | 4749 | 4814 | 5775 | 6823 | 7958 | 5987 | 7125 | 8362 | 9698 | 7687 | 9021 | 10462 | 12011 | 9950 | 11540 | 13247 | 15072 |

| 理论注射重量 | Shot weight (PS) | g | 2662 | 2966 | 3623 | 3977 | 3225 | 3574 | 3941 | 4322 | 4381 | 5255 | 6209 | 7242 | 5448 | 6484 | 7610 | 8825 | 6995 | 8209 | 9521 | 10930 | 9054 | 10501 | 12055 | 13716 |

| 注射压力 | Injection Pressure | Mpa | 194 | 174 | 143 | 130 | 190 | 171 | 155 | 141 | 208 | 173 | 147 | 126 | 213 | 179 | 152 | 131 | 222 | 189 | 163 | 142 | 199 | 171 | 149 | 131 |

| 最高螺杆转速 | Max screw speed | rpm | 150 | 150 | 125 | 125 | 100 | 100 | ||||||||||||||||||

| 锁模系统 | Clamping Unit | |||||||||||||||||||||||||

| 锁模力 | Clamping Force | kN/T | 7500/750 | 9000/900 | 12000/1200 | 14000/1400 | 17000/1700 | 22000/2200 | ||||||||||||||||||

| 开模行程 | Opening stroke | mm | 1000 | 1100 | 1250 | 1350 | 1580 | 1900 | ||||||||||||||||||

| 拉杆内间距 | Tie-bars distance | mm | 1020x970 | 1125x1085 | 1260x1200 | 1360x1300 | 1620x1480 | 1800x1600 | ||||||||||||||||||

| 最大模厚 | Max.mold height | mm | 960 | 1100 | 1300 | 1400 | 1550 | 1700 | ||||||||||||||||||

| 最小模厚 | Min.mold height | mm | 400 | 500 | 500 | 600 | 650 | 650 | ||||||||||||||||||

| 顶出行程 | Ejection stroke | mm | 280 | 335 | 325 | 360 | 425 | 450 | ||||||||||||||||||

| 顶出力 | Ejection force | kN | 212 | 216 | 245 | 264 | 400 | 450 | ||||||||||||||||||

| 其它 | OTHERS | |||||||||||||||||||||||||

| 电马达功率 | Motor power | kW | 50+50 | 50+50 | 62+62 | 50×3 | 62×3 | 62×4 | ||||||||||||||||||

| 加热功率 | Heating capacity | kW | 54.3 | 61.3 | 60 | 87 | 106 | 120 | ||||||||||||||||||

| 油箱容量 | Oiltank Capacity | Litre | 1000 | 1315 | 2000 | 1672 | 2000 | 3500 | ||||||||||||||||||

| 机器尺寸 | Machine Dimensions | m | 11.43×2.4×3.14 | 11.7×2.8×3.1 | 11.5×2.6×3.12 | 14.1×3.1×3.15 | 16.3×3.6×3.5 | 16.8×3.8×4.3 | ||||||||||||||||||

| 机器重量 | Machine weight | Kg/T | 33 | 45 | 55 | 80 | 118 | 130 | ||||||||||||||||||

| 模板尺寸 |  |

|

|

|

|

|

||||||||||||||||||||

1.Five diagonal hinges twin toggle clamping mechanism

2.Electronic ruler control of opening and clamping

3.Mechanical safety mechanism

4.Pressure, speed and location control of multistage opening and clamping

1.Double cylinder paralleled injection system

2.Anti-fatique and corrosion resistant screw charging barre

3.Multi-stage controlof speed, pressure and time of injection, pressure maintaining and storing

4.Position or time of injection turning to pressure maintaining control

5.Detection of residual material at the injection position

6.Electronic ruler control ofiniection position

7.Function of preventing cold start of screw

8.Low speed large torque hydraulic motor preplasticizing

9.Closed loop control of charging barrel temperature

10.Blanking bucket

1.Self-sealing magnetic oil absorption and filtering system

2.Oil temperature detection and alarming function

1.Large screen color LCD display

2.Mold memory function of 100 sets of computer memory

3.Temperature deviation display and thermocouple circuit breaking and alarming function

4.Real time monitoring running status of all actions

5.System hardware l/O detection function

6.Allow ports of printer and floppy drive

7.Safety protection function of motor

8.Emergency stop protection unit

9.Multi-stage ejection mode

10.Automatic mold adjustment function

11.Low pressure mold protection function

12.T-slot

13.Automatic central lubrication system

14.Mold cooling water splitter

1.Exchangeable of close clamping unit and injection unit

2.DFEE electronic closed loop pump control system

3.Dedicated screw for special raw material

4.Synchronous ejection unit

5.Spring nozzle, lengthened nozzle and hydraulic nozzle

6.Screw speed measuring unit

7.Multi-circuit hydraulic system

8.Accumulator aided rapid injection unit

9.Core pulling unit

10.Air blowing unit

11.Template heat insulation board

12.Transparent tube cooling flowmeter

13.Control unit of automatic safety gate

14.Blanking exit cooling and temperature control system

15.Oil temperature preheating function

16.Constant temperature control system of oil temperature

17.Magnetic stand of blanking bucket

18.Photoelectric detection of mold

19.Proportionate back pressure unit

20.Internet remote monitoring system

21.Hydraulic safety lock

22.SPC electronic sorting unit

1.All kinds of mold

2.Gas aided injection unit

3.Mechanical arm and conveying belt

4.Mechanical arm and conveying belt

5.Mold temperature controller

6.Drving blanking bucket and vacuum material delivery

7.Cooling tower

8.Grinder

9.Mixer

1.Adiustable shockproof foot pad

2.Common tools

3.Instruction manual of machine

4.Tool kit

Enhance the core competitiveness of customers Create higher value for customers