Fresh fruits, vegetables and other agricultural and sideline products have increasingly become a major consumer product in people's daily life. In order to better ensure high-quality life, a new generation of plastic turnover boxes should be born. Pollution) Hygiene (antifreeze, moisture-proof, mildew-proof, anti-mildew) Safety (no thorns, no radiation, non-toxic and tasteless) Convenience (no repair, easy handling) Compression resistance and other advantages. The product is injection molded from plastic raw materials + secondary materials (plastic recycled materials), and is divided into two types: high-density polyethylene (HDPE) and polypropylene (PP). It has been widely used in the international and domestic markets, and is favored by consumers, fruit and vegetable wholesalers, and relevant people in the warehousing and transportation industry. In order to better meet and promote market demand, Chongsheng Machinery has developed a special injection molding machine for the production of fruit frames. On the basis of the design platform of Chongsheng F2 traditional variable pump and Sek economical Tongfu energy-saving injection molding machine, the special injection molding machine for Haishi fruit frame responds to the characteristics of raw materials in the industry, and specially makes high wear-resistant double-alloy screw barrels and easy-to-replace non-dismantling injectors, which are widely used in fruit box products of various molding sizes.

Contact us,buy a special injection molding machine for fruit frames at the best price.

Optimised platen designs to disperse stress and enhance product repeatability

Optimised toggle designs to ensure smooth platen movements and accurate stopping position

Linear guide rail realised high precision and low friction carriage movements which effectively lowered mechanical back pressure and overall energy consumption

The clamping machine of the injection molding machine adopts special heat treatment technology compared with the steel sleeve. The wear resistance is several times that of the ordinary steel sleeve, and the cylinder liner wears less, which can greatly prolong the clamping accuracy, reduce maintenance costs, and improve the starting rate of the injection molding machine

The amount of glue injection has increased significantly. Compared with the old special machine, it is more suitable for the production of heavy products. The glue melting efficiency has increased by more than 50% compared with the old one, which greatly shortens the production cycle

8-Inch color display computer control

| 说 明 | HS330FC | HS450FC | HS530FC | 说 明 | HS630FC | HS750FC | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 注射装置 | 注射装置 | ||||||||||||

| 螺杆直径 | MM | 70 | 75 | 90 | 95 | 95 | 100 | 螺杆直径 | MM | 100 | 105 | 110 | |

| 螺杆长径比 | L/D | 21 | 19.7 | 21 | 19.8 | 22 | 21 | 螺杆长径比 | L/D | 21 | 19.8 | 20 | |

| 理论注射容积 | CM3 | 1346 | 1545 | 2486 | 2770 | 2834 | 3140 | 理论注射容积 | CM3 | 3140 | 3462 | 4369 | |

| 注射重量 | g | 1225 | 1406 | 2262 | 2520 | 2579 | 2857 | 注射重量 | g | 2857 | 3150 | 3976 | |

| 注射压力 | Mpa | 152 | 132 | 138 | 124 | 148 | 134 | 注射压力 | Mpa | 134 | 122 | 123 | |

| 螺杆转速 | rpm | 200 | 200 | 200 | 200 | 180 | 170 | 螺杆转速 | rpm | 170 | 170 | 150 | |

| 锁模装置 | 锁模装置 | ||||||||||||

| 锁模力 | kn | 3300/330 | 4500/450 | 5300/530 | 锁模力 | kn | 6300/630 | 7500/750 | |||||

| 开模行程 | mm | 720 | 800 | 860 | 开模行程 | mm | 910 | 1000 | |||||

| 拉杆内间距 | mm | 725x675 | 825x775 | 865x805 | 拉杆内间距 | mm | 920x865 | 1020x970 | |||||

| 最大模厚 | mm | 680 | 800 | 830 | 最大模厚 | mm | 900 | 960 | |||||

| 最小模厚 | mm | 300 | 330 | 350 | 最小模厚 | mm | 350 | 400 | |||||

| 顶出行程 | mm | 160 | 200 | 241 | 顶出行程 | mm | 295 | 280 | |||||

| 顶出力 | kn | 102 | 113 | 152 | 顶出力 | kn | 152 | 212 | |||||

| 其它 | 其它 | ||||||||||||

| 伺服电马达功率 | KW/HP | 62 | 50+27 | 50+50 | 电马达功率 | KW/HP | 50+50 | 62+50 | |||||

| 加热功率 | KW/HP | 22.8 | 33.5 | 42.8 | 加热功率 | KW/HP | 42.8 | 54.3 | |||||

| 油箱容积 | Litre | 690 | 950 | 950 | 油箱容积 | Litre | 950 | 1000 | |||||

| 外形尺寸 | m | 6.9x1.85x2.35 | 7.5x1.95x2.4 | 8.5x2.2x2.8 | 机器尺寸 | m | 10.2x2.2x2.71 | 11.43x2.4x3.14 | |||||

| 机器重量 | Kg/T | 13.3 | 17.4 | 26 | 机器重量 | Kg/T | 30 | 33 | |||||

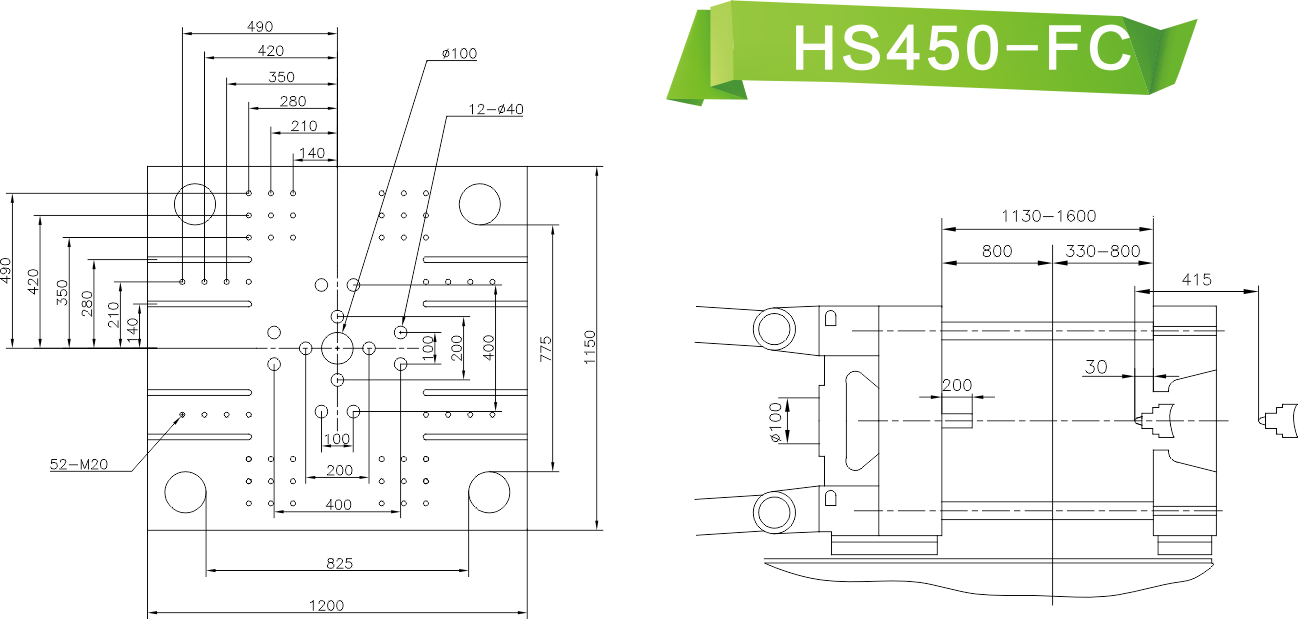

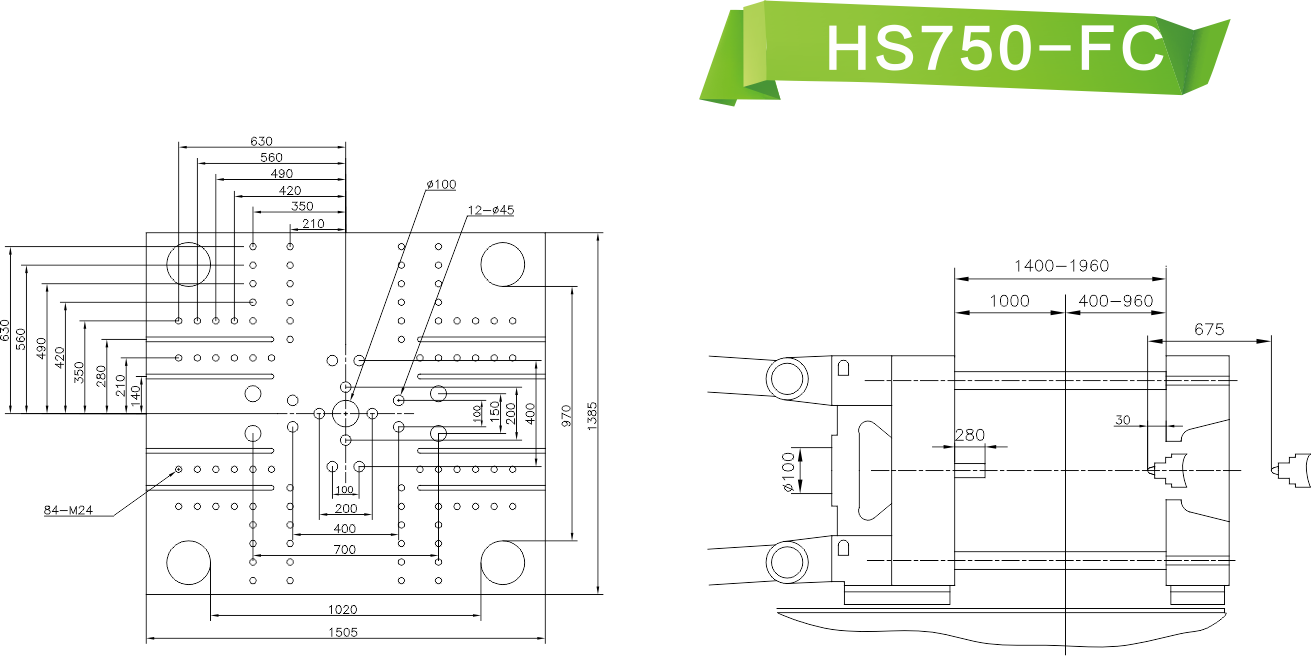

| 模板尺寸 |  |

|

|

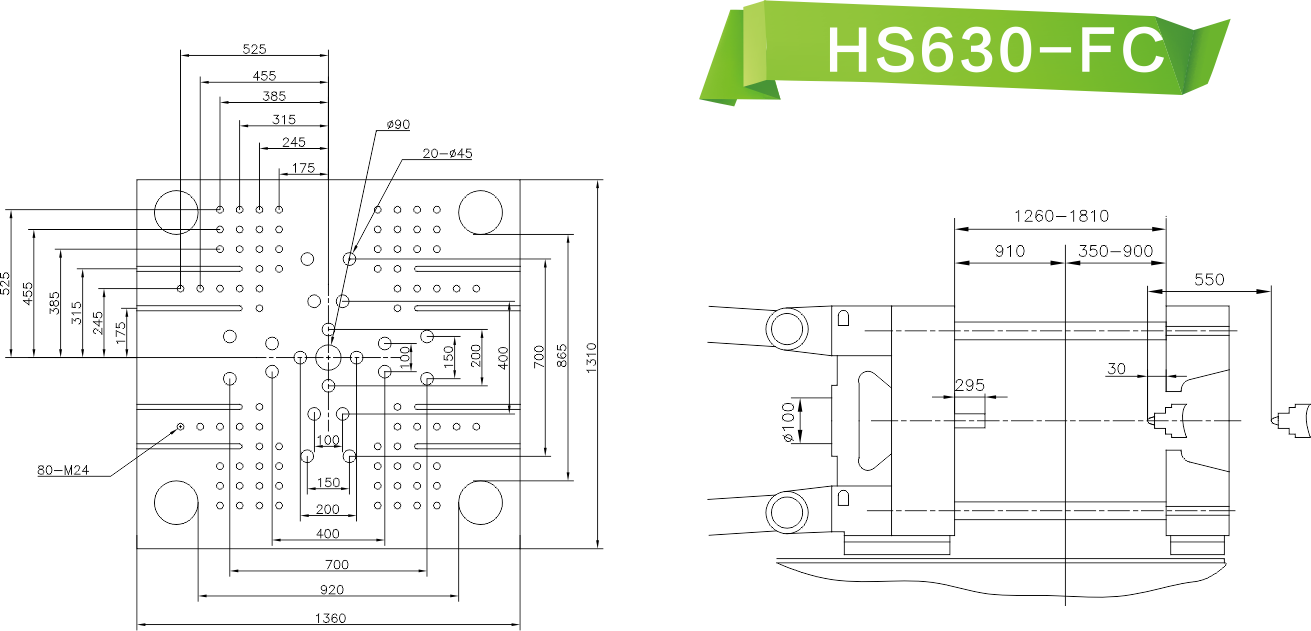

模板尺寸 |  |

|

|||||||

1.Five diagonal hinges twin toggle clamping mechanism

2.Electronic ruler control of opening and clamping

3.Mechanical safety mechanism

4.Pressure, speed and location control of multistage opening and clamping

1.Double cylinder paralleled injection system

2.Anti-fatique and corrosion resistant screw charging barre

3.Multi-stage controlof speed, pressure and time of injection, pressure maintaining and storing

4.Position or time of injection turning to pressure maintaining control

5.Detection of residual material at the injection position

6.Electronic ruler control ofiniection position

7.Function of preventing cold start of screw

8.Low speed large torque hydraulic motor preplasticizing

9.Closed loop control of charging barrel temperature

10.Blanking bucket

1.Self-sealing magnetic oil absorption and filtering system

2.Oil temperature detection and alarming function

1.Large screen color LCD display

2.Mold memory function of 100 sets of computer memory

3.Temperature deviation display and thermocouple circuit breaking and alarming function

4.Real time monitoring running status of all actions

5.System hardware l/O detection function

6.Allow ports of printer and floppy drive

7.Safety protection function of motor

8.Emergency stop protection unit

9.Multi-stage ejection mode

10.Automatic mold adjustment function

11.Low pressure mold protection function

12.T-slot

13.Automatic central lubrication system

14.Mold cooling water splitter

1.Exchangeable of close clamping unit and injection unit

2.DFEE electronic closed loop pump control system

3.Dedicated screw for special raw material

4.Synchronous ejection unit

5.Spring nozzle, lengthened nozzle and hydraulic nozzle

6.Screw speed measuring unit

7.Multi-circuit hydraulic system

8.Accumulator aided rapid injection unit

9.Core pulling unit

10.Air blowing unit

11.Template heat insulation board

12.Transparent tube cooling flowmeter

13.Control unit of automatic safety gate

14.Blanking exit cooling and temperature control system

15.Oil temperature preheating function

16.Constant temperature control system of oil temperature

17.Magnetic stand of blanking bucket

18.Photoelectric detection of mold

19.Proportionate back pressure unit

20.Internet remote monitoring system

21.Hydraulic safety lock

22.SPC electronic sorting unit

1.All kinds of mold

2.Gas aided injection unit

3.Mechanical arm and conveying belt

4.Mechanical arm and conveying belt

5.Mold temperature controller

6.Drving blanking bucket and vacuum material delivery

7.Cooling tower

8.Grinder

9.Mixer

1.Adiustable shockproof foot pad

2.Common tools

3.Instruction manual of machine

4.Tool kit

Enhance the core competitiveness of customers Create higher value for customers